Pressurizing systems

Pressurization

We will distinguish two problems to be solved in this context:

The sealing device that will prevent any leakage between the base and the rocket, then the device that will provide the pressure.

Four sealing devices are found frequently:

|

The cork or better still rubber stopper (like those found in chemical labs), which are drilled in their center to allow the filling hose to pass with water or compressed air. |

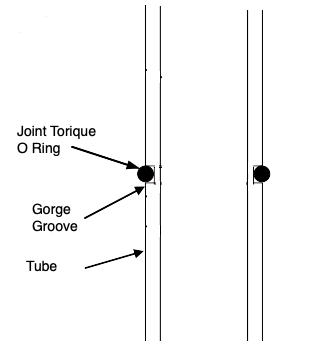

The O-ring, placed in a groove in the rigid air or water supply pipe. |

The Orangina bottle cap pierced with a 20 mm diameter hole in its center, associated with a launcher tube of the same diameter. |

The compressible rubber block, use for bedside lamps |

|

|

|

|

|

Among the devices capable of providing pressure are:

|

|

The simplest system and the safest is the bicycle pump. It will be chosen if possible on foot and equipped with a pressure gauge. It will be prudent to provide a hose extension so as to put pressure at a good distance. |

|

|

There are small electric compressors operating at 12v which can theoretically go up to 10 bars. It will then be necessary to provide a safety valve limiting the pressure to a more reasonable value (5 or 6 bars). However, you should know that the small car compressors generally do not withstand use for very long, either from the water which rises in the compressor or from the excessive heating to which they are subjected. They are indeed not designed to operate for so long (a car tire does not exceed 3 bars, and we rarely start from 0). |

Some eminent amateurs use pressurized gas cylinders (CO2 extinguisher or diving cylinder) with regulators which reduce the pressure to values ??compatible with water rockets. This kind of equipment is only justified for very "enlightened" amateurs. They must be accompanied by pressure relief safety devices.